Cupro Nickel 70 / 30 Sheet & Plate

- Home

- Cupro Nickel 70 / 30 Sheet & Plate

Cupro Nickel 70/30 Sheet & Plate Manufacturer in India

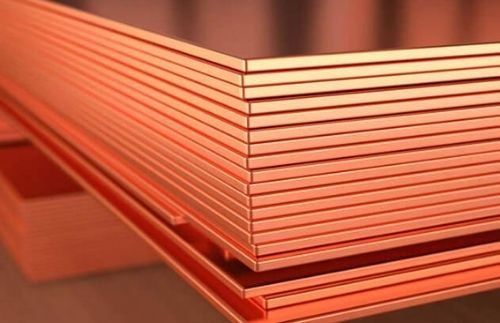

Cupro Nickel 70/30 Sheet & Plate Manufacturer in India, Cupro Nickel 70/30 plate to the clients. They are offering the same at the reasonably priced costs. They are used at the flexible metal hose, boiler parts etc. The plates are used as pump parts, forged valve etc. The product is easily able to retain greater strength over the wider range of temperature and is good for the high-temperature applications. The industry is known popularly as a reliable manufacturer, supplier, stockiest and supplier of the copper-nickel plates at different shapes and sizes to the buyers at reasonable rates.

With regards to the several product quality standards, the product to the buyers is made easily available at different specification.

It thus varies in surface finishes, forms, standards, lengths, standards, types etc. Also on the special request of the buyers, the product is offered at customized specifications.

The fabrication process of the sheet and plate-

The fabrication of the Cupro Nickel 70/30 plate is done at the manufacturing unit with the effective use of high quality of raw materials. The use of latest technology and modern tools are considered so that a very good quality of the product can be manufactured with full effectiveness. The manufacturing of the product is done as per production setup guidelines and according to the product quality standards.

EQUIVALENT GRADE OF Cupro Nickel 70-30 Sheets, Plate & Coils

| STANDARD | WERKSTOFF NR. | UNS |

| Cupro Nickel 70 / 30 | 2.0882 | C71500 |

Cupro Nickel 70 / 30 is also having resistant ability against oxidizing acid chloride, cupric chloride, acetic and formic acid, sea water, brine etc. This nickel provides excellent resistance to the environment where the reducing and oxidizing conditions are encountered at the process streams. Also, it is resisting grain boundary formations at the weld heat affected area, making it perfect for many applications at the welded condition.

To help the industry in bringing out the high quality of the range of cupro nickel plate the industry appoints the well-qualified team of professional experts. They as having good skills and knowledge are easily able to manufacture the very good quality of sheets and plates. Also, the well-qualified quality control team is hired by the industry that is looking at the product quality so that no poor quality of sheets and plates. Moreover, on regular basis, the material testing and inspection are done that assures high quality of product fabrications.

Alloy description-

Cu-Ni 30/70 alloy offers commendable general corrosion resistance ability, particularly at marine salt water atmosphere. The main, wrought copper-nickel alloy selected for the sea-water is containing 10 to 30 percent of nickel alloy. Also, it is having an important addition of manganese and iron alloy that is essential for maintaining excellent corrosion resistance. The common uses of the alloy are valves, marine components etc.

Know about product testing-

Many excellent testing is conducted by the industry to assure the quality of Cupro Nickel 70/30 plate. The ranges of tests conducted are like hardness test, pitting resistance test, positive material identification test, intergranular corrosion test, flattening/flaring test, mechanical/chemical test, chemical test, and mechanical test.

What are the good qualities found in the product

The cupro-nickel sheet and plate easily withstands heavy loads, high temperature, flexibility, durability, anti-corrosive, and long-lastingness. It is having the ability to resists general corrosion, pitting, oxidation, stress corrosion cracking, crevice corrosion and erosion.

MTC that industry to the buyers offers-

The mill test certification or manufacturer test certifications are offered to the patrons in accordance with En 10204/3.1B. Also, the test certifications like 100% radiography test report, third-party test report and a raw material certificate are offered to the buyers.

What essential documents are offered to the buyers

Heat treatment chart, quality assurance plan, fumigation certificate, commercial invoice, material traceability report, lab test report, and raw material test report is provided to the buyers. The main reason behind providing the essential documents is to assure the buyers all about product quality.

The packaging of the product to know-

The Cupro Nickel 70/30 plate are carefully packed in wooden cases, wooden pallets. This is to allow safer transiting of the ordered product. This helps, in faster shipping of the product.

Specification

| Specifications | ASTM B171 / ASME SB171 |

|---|---|

| Width | 1000mm / 1219mm /1250mm / 1500mm / 2000mm |

| Length | 2000 mm / 2440 mm / 2500 mm / 3000 mm / 6000 mm |

| Thickness | 0.5 to 50 mm |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR). |

| Form | Coils, Foils, Rolls, Plain Sheet, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Chemical Composition Of Cupro Nickel 70/30 Plates

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

| Cupro Nickel 70 / 30 | 65.0 min | 1 max | 0.05 max | 29 – 33 | 0.4 – 1.0 | 1 max |

Mechanical Properties Of ASTM B171 Copper Nickel 70 / 30 Sheets

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Cu-Ni 70 / 30 | 0.323 lb/in3 at 68 F | 2260 °F | Psi – 50000 | Psi – 20000 | 30 % |

Cupro Nickel 70/30 Sheet & Plate Manufacturer in India

Siddhgiri Overseas is a top-tier Cupro Nickel 70/30 Sheet & Plate Manufacturer in India, known for delivering high-quality Cu-Ni products across major cities including Mumbai, Delhi, Chennai, Hyderabad, Ahmedabad, Kolkata, and Bangalore. As one of the most trusted manufacturers and suppliers, Siddhgiri Overseas offers premium-grade Cupro Nickel 70/30 Sheets and Plates that meet international quality standards.

Why Choose Siddhgiri Overseas for Cupro Nickel 70/30 Sheets & Plates in India?

At Siddhgiri Overseas, we specialize in manufacturing Cupro Nickel 70/30 Sheets and Plates that offer excellent corrosion resistance, particularly in marine and chemical environments. Our manufacturing facilities located in Mumbai, India, are equipped with the latest machinery to produce top-notch Cu-Ni 70/30 Sheets and Plates.

We are an ISO-certified company, making us a reliable and certified Cupro Nickel 70/30 Plate Manufacturer in India.

Applications of Cupro Nickel 70/30 Sheet & Plate

Our Cupro Nickel 70/30 Sheets and Plates are widely used in various industries including:

Shipbuilding and Marine Applications

Desalination Plants

Power Generation

Heat Exchangers

Oil & Gas Refineries

As a prominent Cupro Nickel 70/30 Sheet Manufacturer in India, Siddhgiri Overseas ensures that every product is thoroughly tested for quality and performance before delivery.

Cupro Nickel 70/30 Sheets & Plates Supplier in Mumbai, Delhi, and Chennai

We supply Cupro Nickel 70/30 Sheets and Plates to several regions including Mumbai, Delhi, Chennai, Pune, Surat, and Jaipur. Our logistics network ensures timely delivery all over India, making us a dependable Cupro Nickel 70/30 Plate Supplier in India.

Whether you are located in Mumbai or Chennai, Siddhgiri Overseas is your go-to destination for the best-quality Cupro Nickel 70/30 Sheets and Plates in India.

Why Cupro Nickel 70/30?

The Cu-Ni 70/30 alloy offers excellent strength, weldability, and resistance to corrosion, particularly in saline water conditions. Siddhgiri Overseas, being a dedicated Cupro Nickel 70/30 Plate Manufacturer in India, uses only certified raw materials to ensure the highest standards in product manufacturing.

Contact Siddhgiri Overseas – The Best Cu-Ni 70/30 Sheet & Plate Manufacturer in India

If you are looking for a reliable Cupro Nickel 70/30 Sheet and Plate Manufacturer in India, look no further than Siddhgiri Overseas. We offer competitive pricing, on-time delivery, and unmatched product quality.

Call us today or visit our facility in Mumbai, India, for all your Cupro Nickel 70/30 Sheet and Plate requirements.